In the fast-paced landscape of modern business, efficient inventory management stands as a cornerstone for organizational success. Yet, traditional methods of tracking assets often fall short, leading to inefficiencies, errors, and lost opportunities. Enter asset tagging systems—a revolutionary solution poised to transform the way businesses handle their inventory.

In the fast-paced landscape of modern business, efficient inventory management stands as a cornerstone for organizational success. Yet, traditional methods of tracking assets often fall short, leading to inefficiencies, errors, and lost opportunities. Enter asset tagging systems—a revolutionary solution poised to transform the way businesses handle their inventory.

The traditional approach to inventory management, relying on manual data entry or barcode scanning, is not only time-consuming but also prone to human error. Misplacements, miscounts, and outdated records plague even the most diligent efforts, resulting in inaccurate inventory levels and unnecessary expenses. However, with the advent of asset tagging systems, a new era of precision and control has emerged.

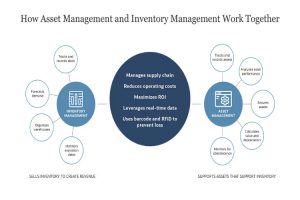

At its core, asset tagging involves affixing unique identifiers, such as barcodes or RFID tags, to individual assets or items within an organization’s inventory. These tags serve as digital fingerprints, enabling swift and accurate tracking throughout the entire asset lifecycle. Unlike traditional methods, asset tagging systems offer real-time visibility into inventory levels, locations, and movements, empowering businesses to make informed decisions with confidence.

The benefits of asset tagging systems extend far beyond mere inventory accuracy. By automating data collection and streamlining workflows, organizations can significantly reduce labor costs and operational overhead. Moreover, the ability to proactively monitor asset utilization and maintenance schedules ensures optimal resource allocation and prolongs asset lifespan.

In this article, we are going to explore the myriad ways in which asset tagging systems revolutionize inventory management. From enhancing accountability and security to facilitating compliance with regulatory requirements, these systems represent a paradigm shift in how businesses approach asset tracking. Join us as we explore the transformative potential of asset tagging systems and unlock new avenues for operational excellence.

Enhanced Visibility and Accuracy

- Real-time Tracking:Asset tagging systems provide instantaneous visibility into the location and status of assets across multiple locations. With automated data capture, organizations can monitor inventory movements in real time, minimizing the risk of loss or misplacement.

- Precision Inventory Control:By assigning unique identifiers to each asset, such as barcodes or RFID tags, businesses can accurately track inventory levels without manual intervention. This precision enables proactive inventory management strategies, such as just-in-time ordering and demand forecasting, optimizing stock levels and reducing carrying costs.

- Error Reduction:Manual inventory tracking methods are susceptible to human error, leading to discrepancies in recorded inventory levels. Asset tagging systems mitigate this risk by automating data collection and eliminating data entry errors. As a result, organizations can rely on accurate, up-to-date inventory information for decision-making purposes.

- Auditing and Compliance:Asset tagging systems facilitate seamless audits and compliance verification processes. With comprehensive records of asset movements and transactions, organizations can easily demonstrate adherence to regulatory requirements and internal policies. This capability not only streamlines audit procedures but also enhances accountability and transparency.

Operational Efficiency and Cost Savings

- Streamlined Workflows:

Asset tagging systems streamline inventory management workflows by automating repetitive tasks, such as asset identification and data entry. This automation frees up valuable time and resources, allowing employees to focus on more strategic activities that drive business growth.

- Reduced Labor Costs:

Manual inventory tracking methods demand significant labor hours for data entry, reconciliation, and physical inventory counts. Asset tagging systems minimize the need for manual intervention, leading to substantial savings in labor costs over time.

- Optimal Resource Allocation:

By providing insights into asset utilization patterns, asset tagging systems empower organizations to optimize resource allocation. Businesses can identify underutilized assets, redistribute resources as needed, and eliminate unnecessary purchases, resulting in cost savings and improved operational efficiency.

- Preventive Maintenance:

Asset tagging systems enable proactive maintenance scheduling based on asset usage and condition data. By identifying maintenance needs before they escalate into costly repairs, organizations can prolong asset lifespan, minimize downtime, and reduce maintenance expenses.

- Scalability and Future-Proofing:

Asset tagging systems are scalable solutions that can accommodate growing inventory volumes and evolving business needs. Whether expanding operations or introducing new product lines, organizations can seamlessly integrate additional assets into existing tagging systems, ensuring long-term viability and return on investment.

Enhanced Security and Loss Prevention

Asset tagging systems bolster security measures by providing a robust framework for asset tracking and monitoring. With unique identifiers assigned to each asset, organizations can implement access controls and security protocols to prevent unauthorized removal or misuse. Additionally, in the event of theft or loss, asset tagging systems facilitate swift recovery efforts through detailed asset records and tracking capabilities. By enhancing security measures, businesses can mitigate the risk of asset shrinkage and safeguard valuable resources.

Moreover, asset tagging systems serve as a deterrent to theft and unauthorized asset transfers. Visible asset tags act as a visual deterrent to potential thieves, signaling that assets are closely monitored and traceable. Furthermore, with the ability to track assets throughout their lifecycle, organizations can quickly identify and address any discrepancies, discouraging internal theft or misuse. Overall, by enhancing security and loss prevention measures, asset tagging systems contribute to a safer and more secure operating environment.

Conclusion:

The implementation of asset tagging systems marks a paradigm shift in inventory management, offering unparalleled efficiency, accuracy, and control. By harnessing the power of digital identification and automated tracking, businesses can overcome the limitations of traditional inventory management methods and unlock new opportunities for growth and optimization.

Asset tagging systems provide organizations with real-time visibility into their inventory, enabling proactive decision-making and strategic planning. With precise data on asset locations, movements, and usage patterns, businesses can optimize resource allocation, minimize operational costs, and enhance overall productivity. Moreover, the enhanced security measures offered by asset tagging systems mitigate the risk of theft, loss, and unauthorized asset transfers, fostering a safer and more secure operating environment.

Furthermore, the seamless integration capabilities of asset tagging systems ensure compatibility with existing enterprise systems, facilitating streamlined workflows and data exchange processes. Whether operating in manufacturing, retail, healthcare, or any other industry vertical, organizations can leverage asset tagging systems to streamline operations, improve compliance, and drive business success.

As businesses navigate the complexities of today’s dynamic market landscape, the importance of efficient inventory management cannot be overstated. Asset tagging systems represent not only a solution to the challenges of traditional inventory tracking but also a catalyst for innovation and transformation. By embracing the capabilities of asset tagging systems, organizations can position themselves for long-term success, driving operational excellence, and staying ahead of the competition in an ever-evolving business environment.

Disclaimer: “This article is for educational & entertainment purpose.”